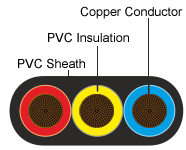

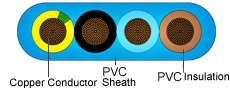

| Cable Structure | |

|---|---|

| Generally Conforms to, BS EN 50525, CENELEC HD 21, UL-83, IEC 60227, BS 6500, DIN VDE 0281, IS 694 | |

| Copper | EC flexible copper as per ASTM B-3, IEC 60228, DIN VDE 0295 |

| Insulation as per TW,THW,THHW,THW-2 | |

| * Any other Color on specific request can also be supplied | |

| Technical Data | |

|---|---|

| Technical data PVC pump cable | |

| Insulation | Special PVC- as per UL 83 |

| Outer Sheath | Special PVC- as per UL 83 |

| Operating Temp | -40°c to max.+90°C |

| Nominal voltage | 600 V |

| Test voltage | 2000 V |

| Flame propagation | Flame retardant test as per UL 83, VW-1 |

| Technical data Rubber pump cable | |

| Insulation | Special PVC- as per UL 83 |

| Outer Sheath | Special PVC- as per UL 83 |

| Operating Temp | -40°c to max.+90°C |

| Nominal voltage | 600 V |

| Test voltage | 2000 V |

| Flame propagation | Flame retardant test as per UL 83, VW-1 |

| Application | |

|---|---|

| AWG Pump Cables designed for use as submersible pump, deep well and motor lead cable. | |

| it works Up to the depth of 500 m and water temperature up to +90°C . | |

| Cables are designed and manufactured to achieve the highest possible degree of reliability. | |

| Features | |

|---|---|

| Cable features (PVC Pump Cables) | Cable features (Rubber Pump Cables) |

| Exceptional long term performance | 90°C oil, zone & water resistant rubber insulation |

| Suitable for 90°C dry & 75°C wet | Exceptional long term performance |

| Excellent resistant to oils, chemicals, ozone & solvents | RoHS compliance |

| Excellent Electrical Properties and Excellent Impact, Weather Resistant performance | Excellent resistant to oils, chemicals, ozone & solvents |

| Tested by INTERTEK, SGS, EIL, RITES, NPC | Excellent Electrical Properties and Excellent Impact, Weather Resistant |

| Tested by INTERTEK,SGS, EIL, RITES, NPC | |

| Cable Design |

|---|

| A Submersible Pump Cable is a specialized product to be used for submersible pump in a deep well. The area of installation is physically restrictive, and the environment is very hostile. Voltson is designed and manufacured keeping in mind these factors to achieve the highest possible degree of reliability. |

| Core Color : Core Indentification | ||

|---|---|---|

| Color Coding | AS Per UL 83 | |

| 3 Core without ground | Red, Yellow and Black | |

| 4 Core with ground | Red, Yellow, Black and Green | |

| Flat Jacketed Submersible Pump Cables Without Ground | ||||

|---|---|---|---|---|

| Cross sectional area of conductor | No of conductor | Configuration | Nominal thickness of sheath | Mean overall dimeter width x height |

| AWG | Nos. | Nos. x Dia | mm | mm |

| 14 | 3.0 | 41 x 0.254 | 1.15 | 14.60 x 6.40 |

| 12 | 3.0 | 65 x 0.254 | 1.15 | 16.80 x 7.40 |

| 10 | 3.0 | 105 x 0.254 | 1.15 | 18.70 x 7.90 |

| 8.0 | 3.0 | 168 x 0.254 | 1.4 | 23.70 x 9.90 |

| 6.0 | 3.0 | 226 x 0.254 | 1.4 | 28.00 x 11.40 |

| 4.0 | 3.0 | 420 x 0.254 | 2.0 | 35.50 x 14.70 |

| 2.0 | 3.0 | 665 x 0.254 | 2.0 | 39.50 x 16.20 |

| 1.0 | 3.0 | 817 x 0.254 | 2.2 | 45.50 x 18.30 |

| 1/0 | 3.0 | 1330 x 0.254 | 2.2 | 51.00 x 20.00 |

| 3/0 | 3.0 | 1672 x 0.254 | 2.4 | 60.00 x 23.50 |

| 4/0 | 3.0 | 2116 x 0.254 | 2.65 | 65.00 x 25.00 |

| Flat Jacketed Submersible Pump Cables With Ground | ||||

|---|---|---|---|---|

| Cross sectional area of conductor | No of conductor | Configuration | Nominal thickness of sheath | Mean overall dimeter width x height |

| AWG | Nos. | Nos. x Dia | mm | mm |

| 14 | 4.0 | 41 x 0.254 | 1.15 | 18.00 x 6.50 |

| 12 | 4.0 | 65 x 0.254 | 1.15 | 21.00 x 7.60 |

| 10 | 4.0 | 105 x 0.254 | 1.15 | 24.30 x 7.90 |

| 8.0 | 4.0 | 168 x 0.254 | 1.4 | 29.70 x 9.90 |

| 6.0 | 4.0 | 226 x 0.254 | 2.0 | 36.00 x 11.80 |

| 4.0 | 4.0 | 420 x 0.254 | 2.0 | 45.10 x 14.70 |

| 2.0 | 4.0 | 665 x 0.254 | 2.2 | 50.10 x 16.20 |

| 1.0 | 4.0 | 817 x 0.254 | 2.2 | 58.10 x 19.00 |

| 1/0 | 4.0 | 1045 x 0.254 | 2.2 | 58.10 x 19.00 |

| 2/0 | 4.0 | 1672 x 0.254 | 2.2 | 66.50 x 21.50 |